Realignment - Vertical

reduce grade (travelling down steep grades can cause brake failure, for heavy vehicles in particular, while travelling up steep grades must be done slowly in some vehicles, and can result in overtaking crashes and poor traffic flow). increase the radius of a crest for adequate sight distance (by “shaving” the top off of the crest) minimise vertical acceleration changes (for example, sag curves can be very uncomfortable for vehicle occupants address drainage problems (water can collect in sag curves, causing a safety problem).

Reduced risk of head-on, intersection and overtaking crashes. Reduced risk of vehicle equipment failure (steep grades). More uniform traffic flow.

Vertical curve realignments require a lot of design and construction effort, and a lot of time and money. It is much better to design the road well before it is built than to rebuild it. Horizontal and vertical alignments should be considered together. Poor combinations of vertical and horizontal alignment can confuse drivers and lead to dangerous situations. Vertical realignment can result in existing side roads joining the main road at excessive gradient. For side roads joining from a lower height, this entails increased risk of collision due to slow turning manoeuvers at restart and visibility problems. For side roads joining from higher grounds, this entails increased risk of vehicles overrunning the stop line. Therefore, vertical realignment often requires concurrent treatment of side roads. Realignment can have significant environmental impacts due to increased footprints and earthworks.

Treatment Summary

10-25% |

Case Studies

Related Images

An upgraded intersection with protected turn lane, involving horizontal and vertical realignment. Image credit: ARRB Group

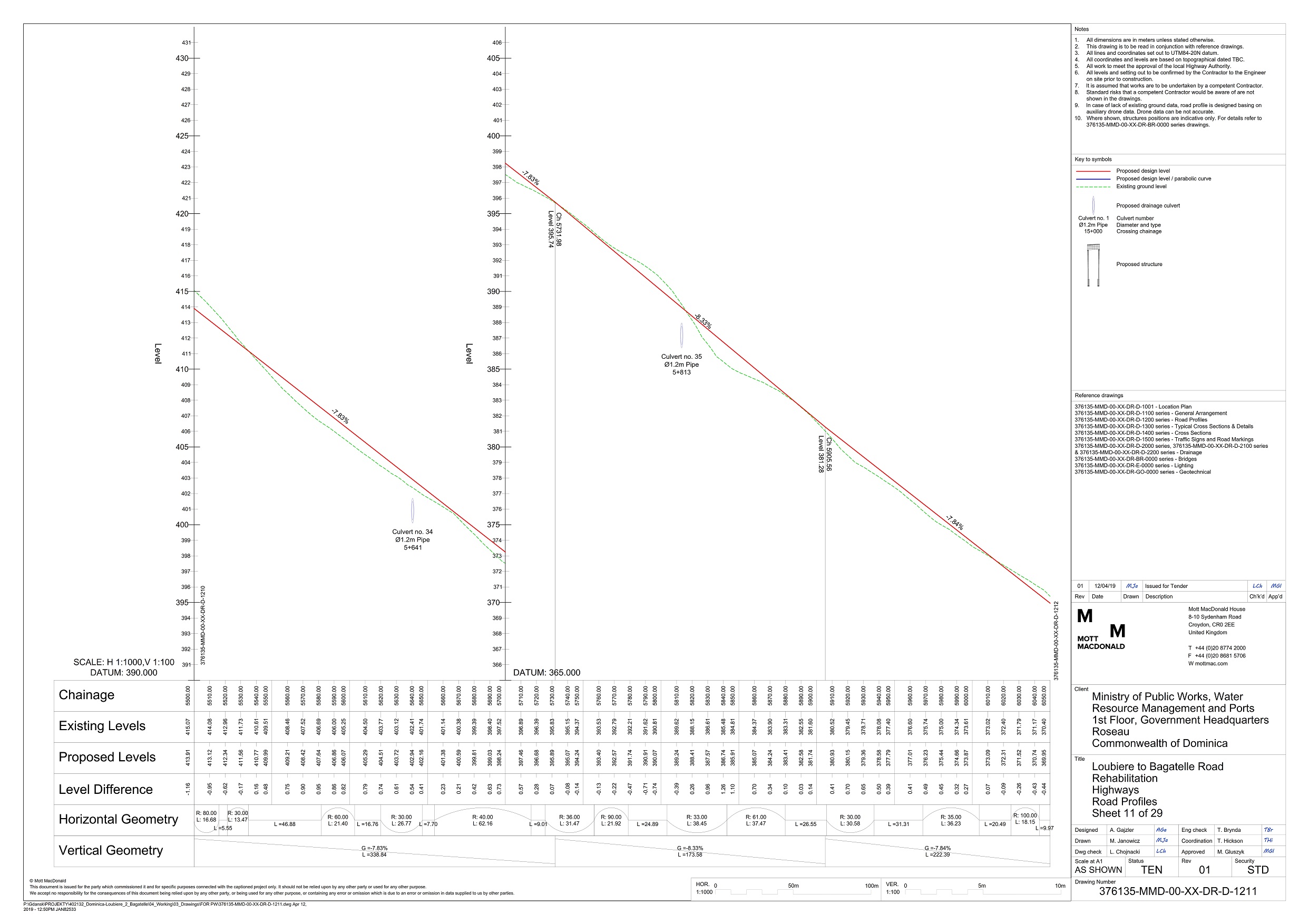

A design showing a planned vertical realignment of a road in Dominica. Image credit: Ministry of Public Works

Example of vertical alignment - India. Image credit: Unknown

Before and after images of a location where alignment and pavement improvements were made in the USA. Image credit: FHWA and NYSDOT